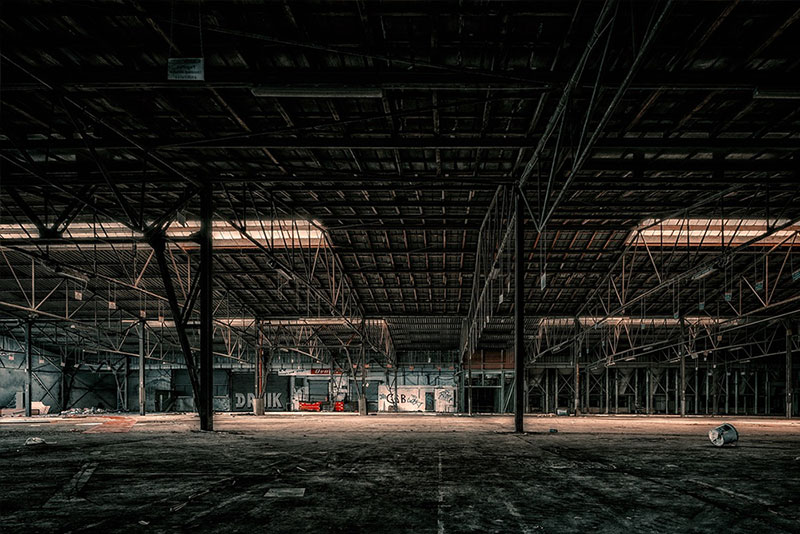

In today's competitive business environment, reducing warehousing overhead costs is essential for maintaining profitability and staying ahead of the competition. Businesses in the United States face numerous challenges when it comes to managing warehousing expenses, including rent, utilities, labor, and inventory management. Implementing effective strategies can significantly impact your bottom line and improve overall operational efficiency. Here are some proven methods on how to reduce warehousing overhead costs in the US:

1. Optimize Warehouse Layout and Space Utilization

One of the most effective ways to reduce warehousing overhead costs is to optimize the layout and maximize space utilization. Conduct a thorough assessment of your warehouse to identify any wasted space or inefficient storage practices. Consider implementing vertical storage solutions, using racks and shelves effectively, and organizing inventory based on frequency of use to minimize unnecessary movements.

2. Improve Inventory Management

Effective inventory management is crucial for minimizing carrying costs and preventing stockouts. Invest in inventory management software that provides real-time data on stock levels and helps in forecasting demand accurately. Adopt lean inventory practices such as Just-in-Time (JIT) inventory to reduce excess inventory holding costs and improve cash flow.

3. Enhance Warehouse Labor Efficiency

Labor costs typically constitute a significant portion of warehousing overhead. To reduce these costs, focus on optimizing labor efficiency. Provide regular training to warehouse staff to improve productivity and reduce errors. Implement efficient picking and packing processes to minimize labor hours per order. Consider outsourcing certain tasks or using temporary labor during peak periods to manage costs effectively.

4. Negotiate with Suppliers and Logistics Partners

Review your relationships with suppliers and logistics partners to negotiate better terms and rates. Consolidate shipments to reduce transportation costs and take advantage of bulk discounts. Explore alternative transportation options or renegotiate contracts with existing carriers to optimize shipping costs. Efficient inbound logistics can lead to significant savings in warehousing overhead.

5. Implement Energy Efficiency Measures

Energy costs can be a substantial part of warehousing overhead. Implement energy-efficient practices such as installing LED lighting, optimizing HVAC systems, and using energy management software to monitor and control usage. Conduct regular maintenance of equipment to ensure optimal performance and reduce energy consumption.

Conclusion

Reducing warehousing overhead costs in the US requires a strategic approach that focuses on optimizing resources, improving efficiency, and controlling expenses. By implementing the strategies outlined above—optimizing warehouse layout, improving inventory management, enhancing labor efficiency, negotiating with suppliers, and implementing energy efficiency measures—you can achieve significant cost savings while enhancing overall operational effectiveness.